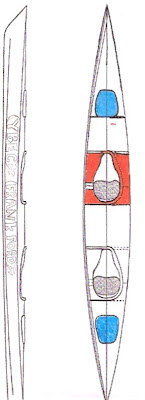

At the YBEC Frankford campus, we have realized several things lately. First, we have not blogged or posted pictures in over a month. Why? Not because the students stopped working on the kayak, in fact, it is quite the opposite. We have been in the midst of not only a month long push to finish the boat, but also a myriad of projects and student activities including starting and working the garden, tending to an ever-growing flock of chickens, adventure trips, and after school clubs such as climbing, skateboarding, and fishing club. Somehow, in the midst of all of that, we have almost completed the boat. Second, we realized a few weeks ago how quickly our four day was coming up, which is when we planned to launch the boat. That launched us into "sweatshop mode" in which students daily sanded, epoxied, fiberglassed, sanded, sanded, sanded, and sanded some more. The third thing we realized as we worked this week was, WE HAVE A BOAT!!!!!!! The kayak is basically finished with the exception of a few finishing touches, and will be carefully lifted out of the art room window (which Lane and I took off of its hinges today.....shhhhhh, don't tell Big Spring School District), and ceremoniously launched next week at Cape Henelopen, Deleware.

Tune back in to the blog shortly to see student's writing and impressions about building the boat, and photos of the final creation. We are so excited to have completed our project, and are continuing to be so impressed with our students and the work they have put into the kayak!!